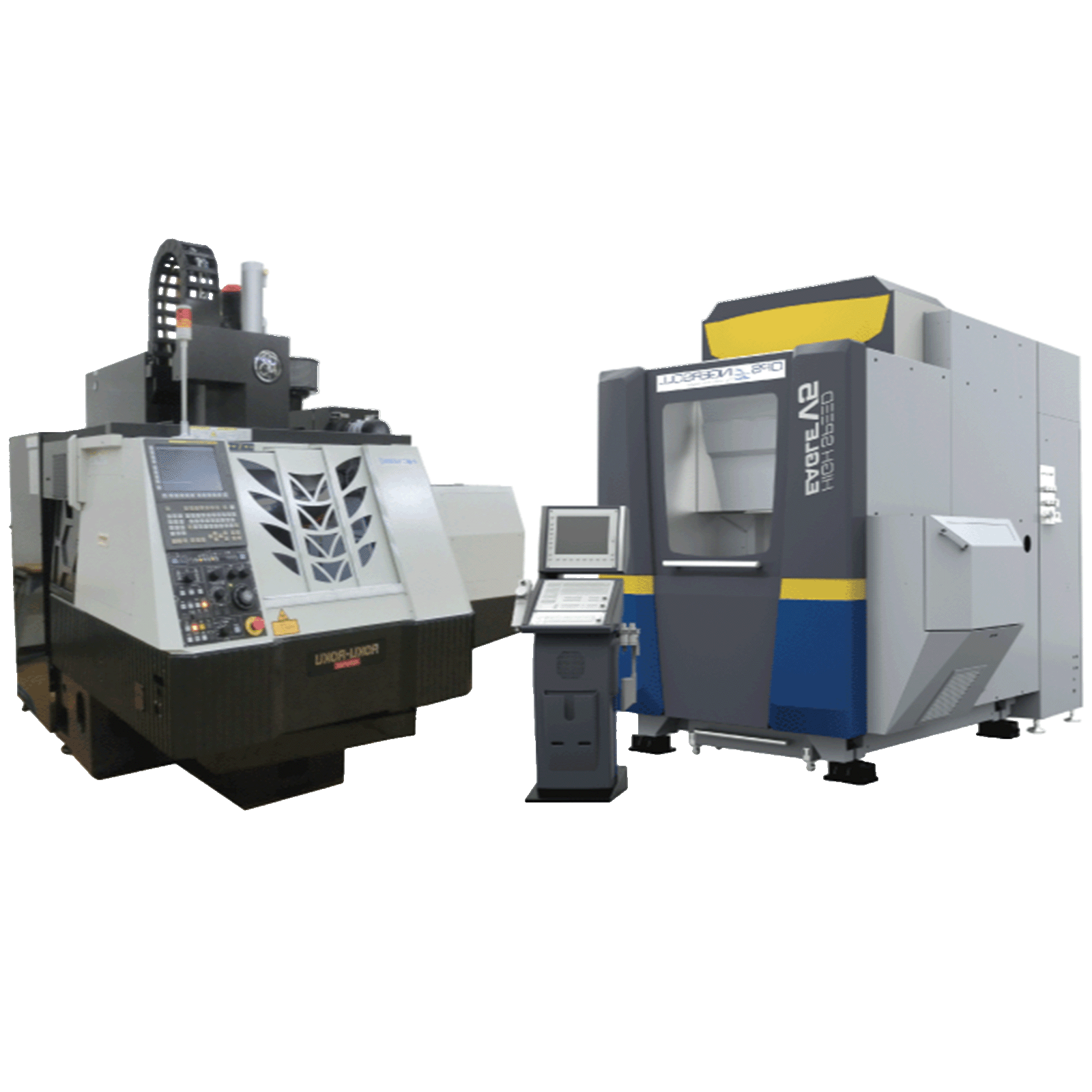

CEGA SSS-300/400

High-speed machining combined with a newly upgraded 20 HP / 30,000 RPM spindle adds heavier machining capability.

For some projects—the kind that requires fast, 精确到1的结果,000th of a millimeter—you need a machine that’s up to the task.

The CEGA SSS-300/400 is capable of a wide speed range (200 – 30,000 RPM), 20马力, or (200 – 40,000 RPM)与7.4-HP using an oil-mist lubricated AC spindle motor.

使用CEGA SSS-300/400, 的成本效益, 高性能, micro-accuracy machining and hard milling capabilities your business needs to achieve top-quality work are finally here—all in one machine.

COST- AND SPACE-EFFICIENT PRODUCTIVITY

- The CEGA SSS-300/400 does exactly what your business needs it to do: deliver high-precision work quickly, 不用倾家荡产. This machine fits amazing machining capabilities into one small, powerful, economical package.

速度快,经久耐用

- The CEGA SSS-300/400 combines rugged construction materials and dynamic internal components to enable continuous operation at max speed—backed up by best-in-class support from our responsive service teams.

高度可扩展的

- The CEGA SSS-300/400 features a highly expandable, modular design to help ensure your investment will remain useful well into the future.

功能:

- 非常适合高速, 高精度铣, 钻井, and tapping due to its “super hybrid concept” design

- 提供高速, high-precision machining with greater stability due to its high-rigidity structure

- Wide speed range (200 – 30,000 RPM), 20马力, or (200 – 40,000 RPM)与7.4-HP using an oil-mist lubricated AC spindle motor.

组件:

- High-rigidity HSK-E40 tool holders

- 双Z轴平衡气缸

用户界面:

- Fanuc 31i-B5 super high-speed processor with AI Contour Control II and NANO interpolation

| Machine Travels: X x Y x Z in (mm) | 20.0 x 16.0 x 12.0 (510 x 410 x 310) |

|---|---|

| 主轴转速:sss300 (sss400) | 200 ~ 30,000 RPM (200 ~ 40,000 RPM) |

| 主轴马力:sss300 (sss400) | 20 (7.4) |

| 主轴润滑 | 油雾 |

| 换刀器尺寸 | 20岗位标准 |

| Positioning Accuracy/Repeatability: in (μm) | ±0.000040/±0.000020 (±1.0/±0.5) |

| 工作台X X Y: in (mm) | 25.5 x 16.0 (650 x 410) |

| Table to Spindle Nose Distance: in (mm) | 5.9 ~ 18.1 (150 ~ 460) |

| 马克斯. 工件重量:lb (kg) | 440 (200) |

| 冷却液罐容量:加仑(L) | 52.8 (200) |

| Table Height from Floor: in (mm) | 29.5 (750) |

| 实际测量圆度(2.0”迪亚. @8 IPM): in (μm) | 0.000044 (1.1) |

| 主轴锥度 | HSK-E40 |

| 主轴空气吹扫 | 标准 |

| 经主轴吹风 | NA |

| 带收集器的油雾 | 标准 |

| 线性尺度X, Y, Z轴 | Heidenhain 0.000002毫米标准 |

| 快速遍历速度:in/min. (米/分钟.) | 590 (15.0) |

| Cutting Speed (Normal Mode): in/min. (毫米/分钟.) | 0.04 – 394 (1 ~ 10,000) |

| Cutting Speed (GR Super PC Mode): in/min. (米/分钟.) | 590 (15.0) |

| 集尘系统 | NA |

| 机器重量:lb (kg) | 11,464 (5200) |

| 机器高度:in (mm) | 100 (2540) |

| Required Floor Space [Machine Unit]: in (mm) | 95.0 x 114.0 (2410 x 2895) |

| 控制单元 | Fanuc 31i-B5 Super High-Speed Processor and Al Contour Control II |

| 功率要求KVA | 200 ~ 220V 32.0 kva |

| 空气供给 | 17.5 cu.ft./min @ 72 psi (0.08 psi.5mpa @ 400NL/min.) |

相关解决方案

-

五轴加工技术

High-speed, high-precision machines with the power and flexibility to meet any challenge.

了解更多 -

直线驱动技术

Hyper-准确的 machinability for tight tolerances and micro-fine work where the details really matter.

了解更多 -

高速加工

Top-of-the-line machinery with added cooling power for consistent performance on mission-critical tasks.

了解更多 -

石墨制造

Multiple solutions and expertise in making graphite electrodes.

了解更多 -

铣削自动化

Multiple solutions and expertise in making graphite electrodes.

了解更多

-

"Not only does the 5-axis capability of the OPS Ingersoll Eagle V5 milling machine enable us to burn parts with less physical electrodes, it also has a robotic tool changer so we can focus more during the day on things that need constant attention."

布拉德·麦克道尔, 质量工具 & 死的总统 阅读案例分析 -

"The OPS Ingersoll 5-axis milling machines are fast, 准确的, easy to operate and have a small footprint."

比尔Yakle, 艾斯林工业的老板 了解更多 -

"The Eagle 800 has burn technology that gives us a competitive advantage because it takes about half the time to burn and uses fewer electrodes, 这样既节省时间又节省金钱. Our goal is to run it all day and all weekend. I like that we also are cutting down on our carbon footprint by using fewer graphite electrodes and less copper wire than before."

史蒂夫(, 零容忍总统 查看案例研究 -

"We used to struggle with tool deflection on deep cuts. Now we’re able to tip that up in a five axis and actually hit on the bottom of the flute. And we’re not getting that tool push anymore. Electrodes are so, so much more 准确的."

乍得卡恩斯, 质量工具 & 我是副总裁 阅读案例分析 -

-

"The kinematics of the Roku-Roku VMCs allow us to run faster feed rates and not sacrifice surface finish or accuracy. The machines are efficient in terms of increased cutter life, reliable Fanuc control and overall machine stability. We can run longer intervals on downstream inspection on parts that the Roku-Rokus machined."

约翰TerBeek, 特贝克模塑公司的合伙人 & 工具 查看案例研究